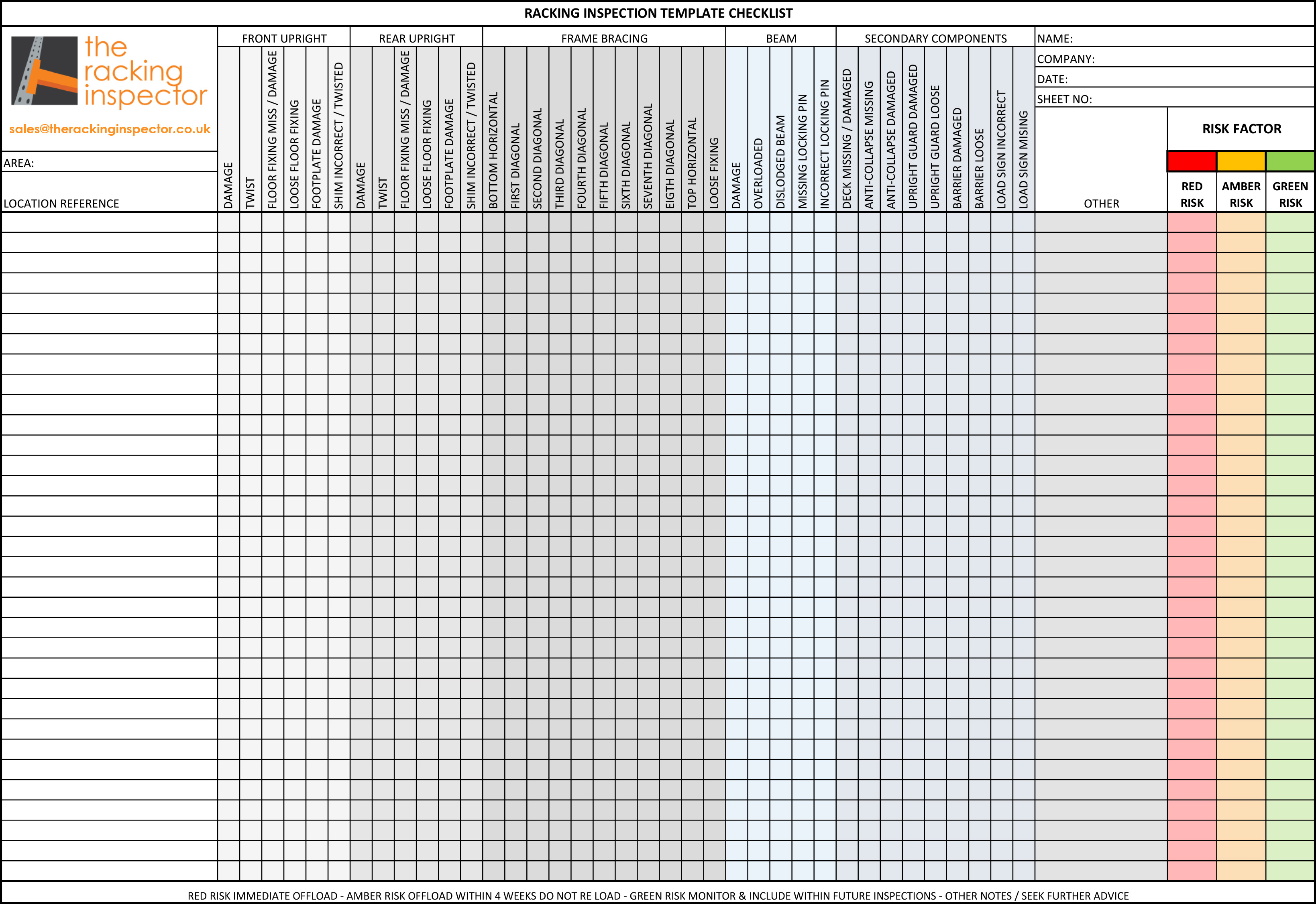

The inspection checklist can be used for frequent inspections by your PRRS (person responsible for racking safety).

If you do not have location labels, a simple layout drawing can be provided following our annual inspection at no additional cost.

The PRRS should have received training on a rack awareness course (Now Available) to identify the correct risk factor and determine the correct course of action required.

For any serious damage or concerns, offload immediately if safe to do so and contact us for further advice.

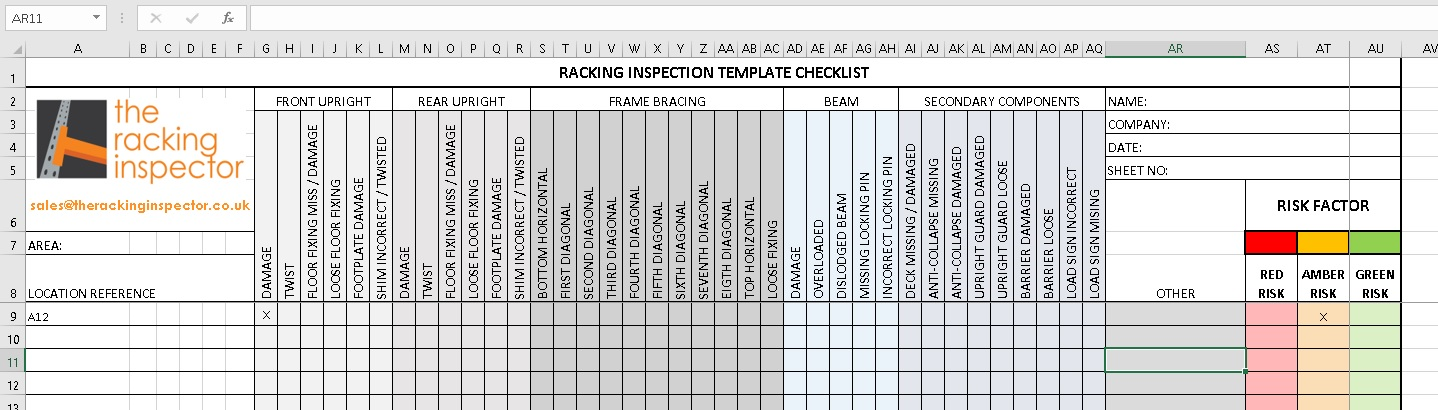

Use the sheet by filling out the location of the damaged component, for example: A damaged front upright section classed as an Amber risk would be completed as follows:

Damage can be recorded for all locations using multiple sheets.

Always ensure each inspection is signed and dated by the PRRS and keep on record for future reference.